“Funding is crucial”

The ramp-up of the hydrogen economy in Hamburg can begin. The Hamburg Green Energy Hub project is receiving significant funding from the German federal ...

By Claudia Behrend

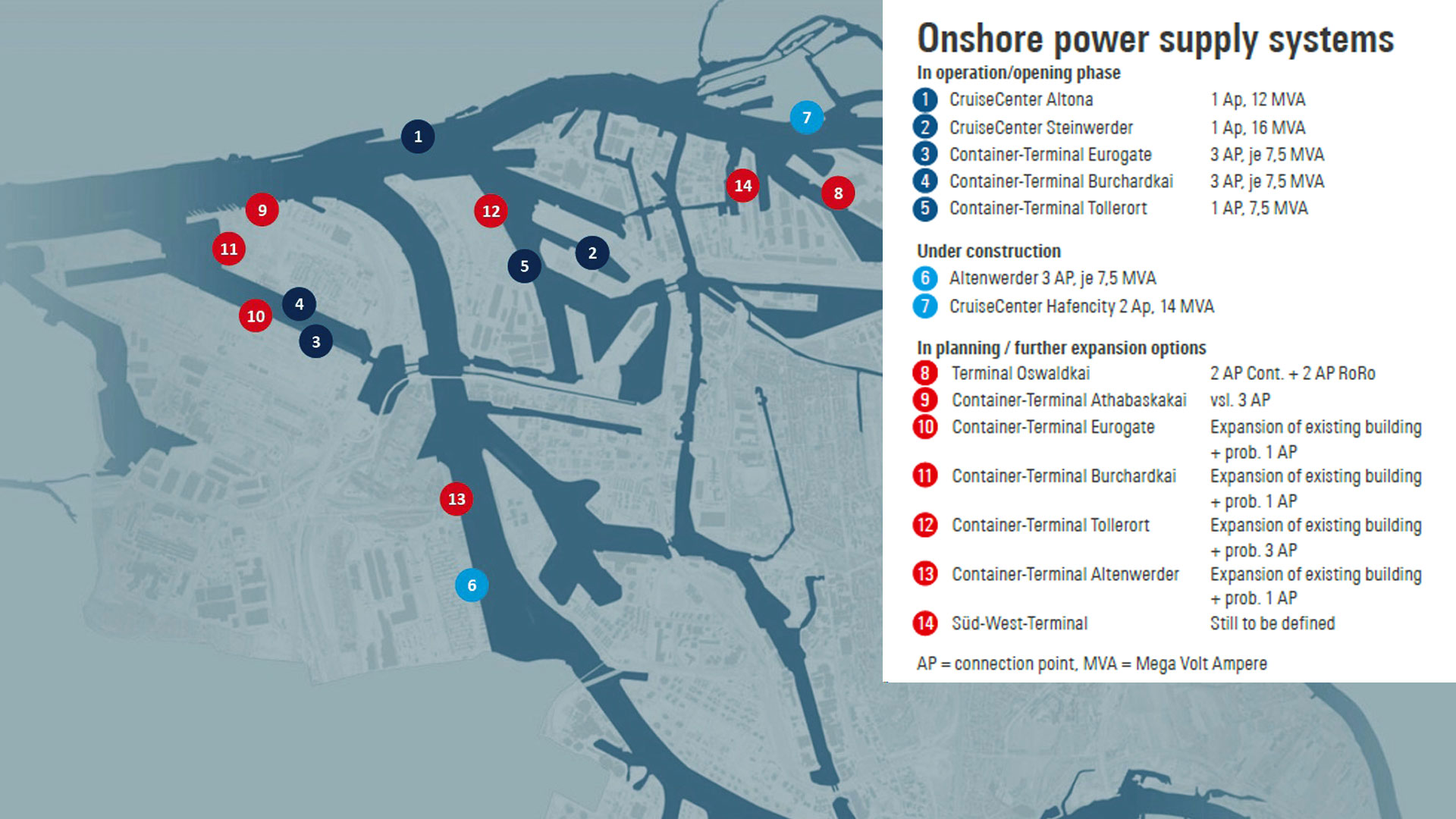

No more smoke billowing into the sky, no more ship engines humming at the berths. Hamburg’s quays are becoming cleaner and quieter. Since 2017, cruise ships have been able to obtain green electricity from the shore while docked in Altona; this has also been possible at the Steinwerder terminal since this year, and a shore power system is under construction at the HafenCity cruise terminal. Since April this year, larger container ships have also been able to do so, starting at Eurogate’s CTH. This makes Hamburg the first European port to offer shore power for both types of vessels.

It may seem like a no-brainer to turn off the auxiliary engines and power the vessel using electricity instead, but this can prove to be a real challenge. It was therefore helpful that the shore power requirement came into force in Los Angeles in 2014, allowing Hamburg to benefit from the experience of the port on the western coast of the United States. But many of the challenges lie in the details: “The shore power system needs to be tailored to each individual ship,” explains Hanno Bromeis, Head of Port Energy Solutions at the Hamburg Port Authority (HPA). This calibration requires an integration test for each vessel, as each vessel is different.

“In Altona, for example, it took two years to adapt the system to the ships,” explains Bromeis. Although many cruise ships call at Hamburg regularly, some only do so once a year. Furthermore, the shore power has to be tested in a variety of conditions, such as extreme tides. “We need an automatic system that follows the tides so that the cables can be readjusted without the need for an operator,” explains Bromeis.

This is done using sensors that constantly monitor the distance to the ship and the water. Since protruding balconies on cruise ships, for example, can cause false readings, the sensors must be trained to avoid these errors. To make matters worse, “the loading hatch is often right next to the shore power hatch, so a separate positioning procedure has to be conducted to allow for loading and unloading by crane while the ship is being supplied.”

Despite all the challenges: shore power has long been available to the majority of cruise ships in Hamburg. “Out of a total of around 280 arrivals per year, more than 200 are capable of being powered from shore,” emphasises Bromeis. Half of the vessels which are not yet able to use shore power are Hurtigruten ships, which are only designed for the Norwegian low-voltage system. The other half are older ships, but retrofitting could be conducted to make this possible. “Whether the investment is worthwhile in terms of area of operation and cost is up to the shipping companies.”

In the future, these are questions that will no longer need to be asked. From 2030, ships with a gross tonnage (GT) of 5,000 or more, including cruise and container ships, will have to be supplied with shore-side electricity throughout Europe. Hamburg will be able to supply larger container ships as early as 2025. Following CTH (Eurogate), the facilities at HHLA’s CTT and CTB terminals will commence operations by the end of this year, while construction work is currently underway at CTA for a planned start of operations in 2025.

“We benefit from the experience of the cruise industry, but the parameters are different,” says Bromeis. For example, the cables have to be routed outside the working area of the container gantry cranes – this is not a challenge encountered in cruise shipping. What is needed is a highly flexible system with movable sockets. “We originally thought that one solution would fit all terminals. But the conditions at the quay wall vary.”

One other major difference: while cruise shipping adheres to the schedule, there is a great deal of dynamism in liner shipping. Sometimes a ship is swapped, sometimes a ship arrives earlier, stays longer or is delayed due to strikes, for example, the need to bypass the Suez Canal via the Cape of Good Hope or the ban on ships meeting on the Elbe.

“Scheduling personnel is much more complicated here because one or two people, including one with switching authorisation, need to be kept on standby.” And the rapid fluctuations also have an impact on the already complex task of power planning. “We have to buy the electricity in a targeted fashion on the market, and may also need to sell it off again based on the circumstances. However, prices for short-term quantities are extremely volatile, which makes planning very difficult,” explains Bromeis.

Different Pricing Models

What’s more, for container ships, shore power is more expensive overall. At 500 to 2,500 kilowatts per hour, basic consumption is much lower than the 1,500 to 13,000 kilowatts cruise ships require. However, at around 60 to 70 hours, the berthing time for container ships is significantly longer than for cruise ships, which spend an average of eight to 10 hours in port. Nevertheless, there is no way around shore power. Hence, the HPA has already signed corresponding agreements with major container lines, including MSC in June and Maersk in August. Further agreements are expected to follow shortly. CMA CGM, Cosco, OOCL and One have already participated in the test phases.

The actual process of connecting takes only about an hour or an hour and a half, but it requires preparation. For example, the transfer system has to be pre-positioned in the right place before the lines make it impossible to do so after docking. Before the physical plug-in connection is made, the person with switching authorisation for the system contacts the crew, goes on board for a safety check and earthing. This person then proceeds to the facility’s control room, conducts the switching briefing with the crew, and the transfer of green power begins.

In order to comply with current EU regulations by 2030, Hamburg will also need to expand its onshore power supply capacity. Over the next few years, the focus will be on feeder berths, so that all container ships can be supplied with sustainable energy by 2030.